Do you know how to reduce the operating costs of RO reverse osmosis water treatment plants?

Do you know how to reduce the operating costs of RO reverse osmosis water treatment plants?

Sep .29.2024

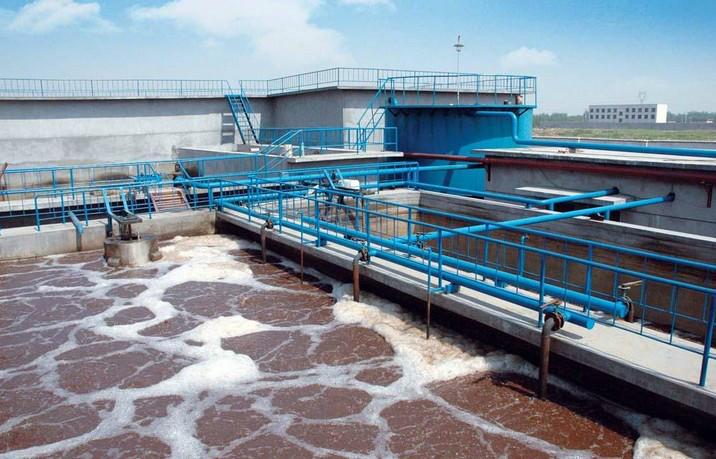

The principle of reverse osmosis technology is higher than the osmotic pressure of the solution, based on other substances can not pass through the semi-permeable membrane and these substances and water to leave.The membrane pore size of the reverse osmosis membrane is very small, so it can effectively remove dissolved salts, colloids, microorganisms, organic matter, etc. in water.RO system because there is a high-pressure pump, and need to add a special scale inhibitor, high operating costs.How do we reduce the operating costs of the RO system?

Do you know what common instruments/meters are needed for reverse osmosis systems?

Do you know what common instruments/meters are needed for reverse osmosis systems?

Sep .29.2024

In order to make the RO device can be safe and reliable operation, easy to monitor the operation process, should be equipped with the necessary instrumentation and control devices, generally need to install the instrumentation has a temperature meter, flow meter, pressure meter, conductivity meter, oxidation potential meter, chlorine meter, pH meter, specific as follows:

Do you know how to reduce the operating costs of RO reverse osmosis water treatment plants?

Do you know how to reduce the operating costs of RO reverse osmosis water treatment plants?

Do you know what common instruments/meters are needed for reverse osmosis systems?

Do you know what common instruments/meters are needed for reverse osmosis systems?

Does your reverse osmosis equipment often wash the membrane, change the membrane?

Does your reverse osmosis equipment often wash the membrane, change the membrane?